In a recap I wrote for the Scene on the big Craft Brewers Conference in May, I cheekily mentioned that I skipped Blackstone Brewing Company founder Kent Taylor’s technical presentation about ways to reduce the risk of boilovers in the brewing process. To his credit, Taylor didn’t take my little jibe personally — in fact, he reached out to discuss what his aims were with the project and the importance of the work his Brewers Association Engineering Subcommittee has been doing.

I’ve long considered Taylor one of the most thoughtful and intelligent brewery operators in our community, so I took him up on the offer to visit his facility and learn more. Before I arrived, he encouraged me to listen to an episode of the Master Brewers Podcast in which Kerry Caldwell describes a harrowing incident: Her brew kettle boiled over and trapped her on the brewers platform, leading to third-degree burns over more than a third of her body.

“I’ve been passionate about this topic for a while,” says Taylor, “and that podcast really affected me.” Popular representations of life in a brewery like on Apple TV+’s Platonic make it seem like a bunch of dudes working together in a fun environment, making their pet-project beers and chatting up customers across the bar in their taprooms. In actuality, brewing beer is very hard work that can sometimes be incredibly dangerous. The process involves steam and boiling liquid and the delicate dance of maintaining temperature and pressure inside huge steel tanks.

Temperatures can quickly get away from a brewer, especially if he or she is busy handling multiple tasks at once. If the wort (a mixture of water and malty sugars) gets too hot, it can quickly expand to overflow the vessel and spew boiling liquid all over the brew deck. The closed lid of the brew tank raises the pressure, and nucleation points can form instantly and violently, like when people accidentally superheat water in a microwave. Even worse, often the controls for the system can be on the wrong side of the brew deck from where the brewer is working, making the only defense against the perilous situation a hose to try to cool down the eruption.

That was the situation Caldwell found herself in, trapped from accessing the controls for the brewhouse and on the wrong side of the tank — in a spot where her brewing assistant couldn’t reach her for help as the sticky water/sugar/grain mixture splashed all over her. In full view of the taproom, she stripped off her boiling hot clothes while her assistant hosed her down from a distance and skin sloughed from her body. Months later, after a medevac to a burn center, multiple skin grafts and constant care, she beat the 66 percent mortality odds her doctors gave her and survived her ordeal.

So, yeah — maybe I should have taken Taylor’s presentation a little more seriously.

Kent Taylor's boilover protection system

Taylor says roughly 80 percent of Brewers Association members do not have boilover protection systems as part of their equipment, citing the expense as an excuse. Taylor set about looking for a cost-effective solution to this conundrum.

“It’s been a three-year project,” he says. “It was frustrating getting $4,000 to $6,000 quotes from manufacturers, so I decided to see if I could do it myself.”

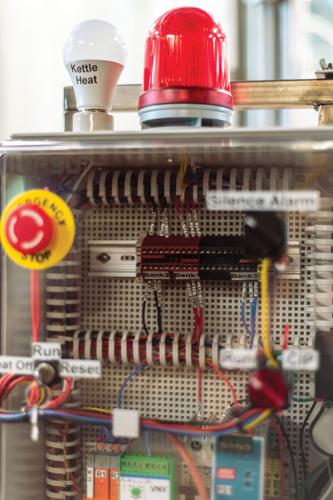

The result is a functioning homemade demonstration pilot system that he constructed using parts sourced from electronics catalogs and through a lot of trial and error. An accountant by trade, Taylor figured that if he could work out the process of building a working boilover protection device, then most people should probably be able to make it work.

His demo unit looks like an award-winning high school science project, and he completed the build for about $1,000. The key component is a conductive sensor that can detect the presence of rising foam in a brew tank, operating the same way a sump pump in your basement senses water and turns on the pump. Taylor designed the system to cut off the heat and sound an alarm as soon as it senses the presence of foam or liquid. “I’ve got it set to immediately cut power to the steam actuator valve, which closes the valve and stops the flow of steam heat,” he says. “In the event of a boilover, you have to cut off the steam, gas or electricity right away, whatever is providing heat to the system.”

His compact demo unit can be easily packed up and carried to show other brewers how it works and how to retrofit it into their own system, but to Taylor’s knowledge, no breweries in Nashville have this sort of boilover protection. “I only finished it two weeks before my presentation at the Brewers Conference,” he says.

Kent Taylor's boilover protection system

But it’s not like the Brewers Association isn’t interested in safety, Taylor says. Indeed, they have all sorts of educational initiatives and programs, but most of them revolve around personal protective equipment, showers, eye wash stations and avoiding slips, falls and drops in the brewery. “Training to avoid accidents is a whole lot cheaper than an OSHA visit, and OSHA only gets involved after the fact,” he says. “If an accountant can design and build one of these things, I’m sure there could be more efficient ways to do it.”

Contrary to Seth Rogen’s happy-go-lucky portrayal of the brew life on Platonic, making beer is a deadly serious business undertaken in an environment of heavy equipment, moving conveyors on canning lines, scalding water, high pressures and potentially explosive steam boilers. Oh, and the floor is almost always wet. Combining these factors means brewhouse employees must pay constant attention to the production process while practicing their arcane art of converting grain, water, hops and yeast into delicious beers.

Taylor wants to stop these sorts of accidents before they occur, and the fact that he dedicated time and resources to coming up with a solution is certainly admirable. If you’re a brewer and want to learn more about his efforts, reach out to him at kent@blackstonebrewery.com. He’d be happy to take more of his time to discuss and demonstrate his project.